AMI Blog: Cost Saving – Right Down to the Core!

Share This

Here at AMI we are always looking for new ways to reduce costs for our clients to help their budgets go further. This year is no exception, and after some extensive R&D and tooling investment, we are pleased to be able to offer a re-core facility.

This new service is great if you have a fleet spare that is requiring replacement or any old coolers in a warehouse waiting to be scrapped. Perhaps you’ve sent us a cooler for cleaning and the fin or tube has shown to be too weak to continue service.

What is a Re-Core and what are the benefits?

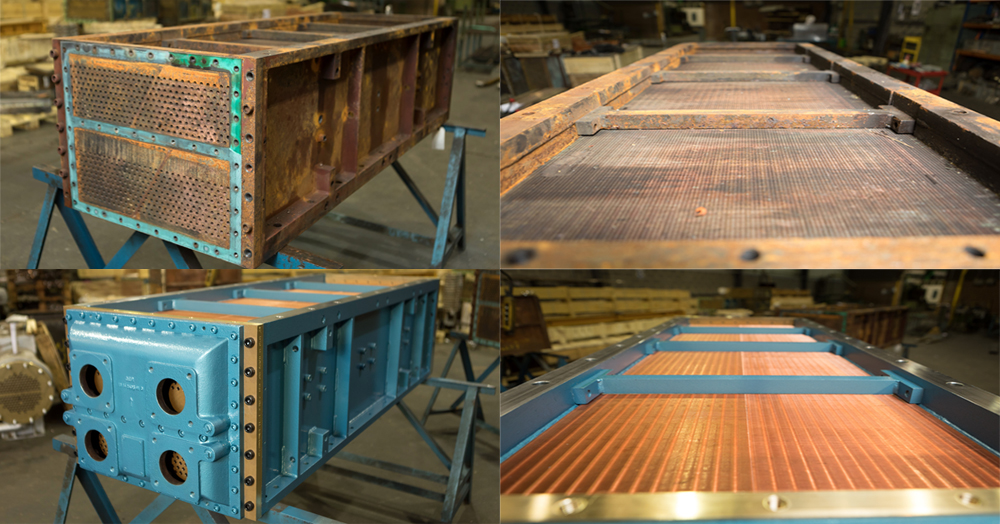

Our new Re-Core process is especially suited to larger charge air coolers, but we can survey most air coolers and assess their suitability for this process. We essentially deconstruct the air cooler, using precision tooling to remove the existing tube ends from the tube plate and remove the side panels leaving us with the original cooling core.

Once the core is exposed, it can be further examined in greater detail, using endoscopes, microscopes and other equipment to identify any areas of particular weakness. This allows us to reverse engineer the new core to be more durable. For example; if the tube is showing signs of vibration-related stress or damage in particular areas, we can potentially change the material of the support plates or even add additional support plates to eliminate this problem in the future.

Now the internals of the cooler have been fully appraised, we then continue the process by testing and reconditioning the side panels and tube plates. At this stage, like with the core, we can identify and engineer design improvements to remedy any problems or damage; shearing of material on the side panels, for example.

Once this has been completed we can then get to work reconstructing the cooler with a brand new core (built from European-sourced materials) and the rest of the components fully restored. We can even refurbish the water end covers.

The benefit to the client is a near-brand new cooler, for a significantly reduced cost. Because we have re-used the side panels and tube plates, costs are reduced and any design improvements we make to the cooler will also provide a longer service life.

Get in touch with us to see how we can help you achieve significant cost savings. We can re-core and supply charge air coolers to replace original types such as Bloksma, GEA, Kelvion, Serck, Vestas and many more.

You can drop us an email on sales@ami-exchangers.co.uk