NOx Compliance

The IMO (International Marine Organisation) identified a need to control emissions from ships back in 1991 and in 1997 after significant deliberation and consultation, introduced Annex VI to the Regulations for the Prevention of air Pollution from Ships. This annex included a staged implementation involving a Tier system that progressively reduced permissible emission levels and this was designed to allow ship owners and technology sufficient time to adapt to these new requirements. Within these regulations, controls and limits have been implemented for those components or settings that could adversely affect NOx emissions from the originally supplied settings – which is the basis of the initial IAPP (International Air Pollution Prevention) certificate supplied with the vessel. Marpol Annex VI and NOx Technical code Regulation 13, applies to marine diesel engines installed into vessels or rigs over 400 gross tonnage, constructed on or after January 2000. Charge Air Coolers are identified as a NOx influencing component and therefore are controlled. In order to renew your IAPP certificate, you will need to demonstrate that you have complied with the specific requirements set out within the NOx technical file. This is irrespective of where you purchase a replacement unit – even from the original engine builders.

So, what information will you need?

The 2013 guidelines issued for Marpol Annex VI and NOx Technical Code 2008 states that the method of verification procedure must be one of the following:

1. Onboard Parameter Check Method. This uses performance, settings and component data stipulated within the Technical file to ensure compliance.

2. Onboard Simplified Measurement Method. A range of engine parameters are regularly measured, recorded and then the NOx levels calculated from this using a pre-defined formulae set out in the NOx technical file. Specific requirements include location, calibration and decimal places of sensors together with sampling methods of fuels and gases.

3. Onboard direct Measurement and Monitoring Method. This involves calibrated emission detectors located within the exhaust stream. The method type and content of the accompanying technical file can vary and is often chosen by the engine builder. We commonly find for main engines that the “parameter check method” is stated within the technical file and for this method, parameters 9 of the rule apply, which states:

“Model and Specification” – this could be a single unique number or a combination of identification number and specification. The specification could in theory be any identifying characteristic of the original air cooler that would be clearly identifiable to a surveyor. This information will be found within the NOx technical file. A “cassette” type charge air cooler is not visible to a surveyor without removal and so the identification numbers may well be found on the water chambers (end covers) or in some cases the outer framework. “Load dependent Charge Air Temperature” – Thermal information is required in order to calculate the outlet temperature of any replacement charge air cooler and this information can be found within the engine “operation and maintenance” file supplied with the vessel. Providing the calculated outlet temperature remains within the limits set within the NOx Technical file, then NOx emissions will remain within limits.

Can the verification method be changed?

Yes and guidelines are available within the regulations describing how to achieve this. A ship owner can change the method to one that suits themselves. For example, should scrubbers be fitted after the vessel has been delivered, the owner may choose to use the “direct measurement method”. All IACS classification societies can and will help you to make the necessary changes.

Can the parameters stipulated within the NOx technical file be changed?

Yes the technical file can contain an amendment which needs to be approved by a classification body. This is relatively common and clients may be unhappy with the components originally supplied for various reasons – such as high cost, poor replacement delivery times, poor performance or poor operational lifespan.

Common misconceptions

Despite the lengthy time since the regulations have been in force, there still remains confusion and/or lack of clarity in this area – both by technical managers and classification surveyors…

“You can only buy replacement parts from the original supplier.”

Whilst engine builders may try to convince you of this, it is simply untrue. The engine’s NOx technical file must be supplied to the vessel upon delivery and this technical document gives all the parameters for all NOx influencing components and the requirements stipulated must be met irrespective of supplier in order to renew your environmental certificate.

“The engine builder did not issue a NOx technical file.”

The IMO regulations stipulate that the technical file must be supplied with the vessel, it must contain all parameters for Nox influencing components or settings and must stay with the vessel. This holds the key information that the class surveyor will require in order to renew the environmental certificate. Without this file you will be unable to renew your certificate.

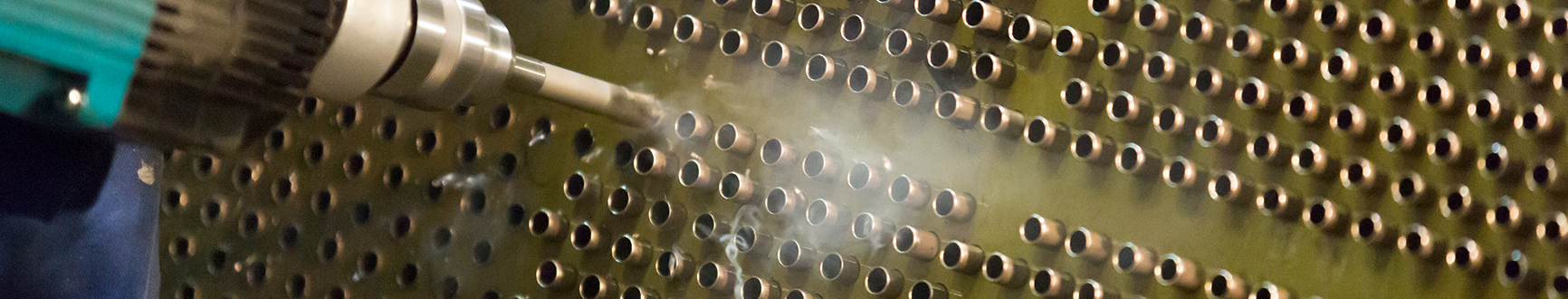

“You cannot repair an old charge cooler”

Again, this is untrue. There are no stipulations for repairs to old units. Units can be in any state of repair providing they meet the parameters stated within the technical file.

“Buying from the original maker will be easier.”

In order for the class society to re-issue the environmental certificate for the vessel, a surveyor needs to check all components and settings using the Nox technical file as reference. This process and the supporting documentation must be supplied to them irrespective of where the replacement is purchased.

Which method would offer the greatest on going freedom and lowest long term costs?

To resolve the above confusion, the high OEM prices and the additional documentation burden, many clients simply retrofit exhaust gas scrubbers and change the verification procedure to the direct monitoring method. This gives many of our clients the greatest operational freedom and many have indicated that this also gives the most economic long term solution.

For more information on how AMI can support your NOx requirements, contact us.